This post will be all about the advantages and capabilities of RFID based carrier tracking.

But before I dive into this – here are the results from the poll from part 1:

Based on this more than half of the legacy FABs have no complete location tracking of all carries in place. In my opinion this is not surprising. A main reason for this situation is that all these FABs are running production for many years and have found work arounds to limit the impact of the missing exact location tracking. A great part of these work around processes play humans – who are able to search and locate carriers. Of course this comes at the cost of spending the time for searching – which reduces FAB productivity.

As competition increases and the ever ongoing fight for reducing the cost per wafer in the FABs leads FAB managers to start thinking about automating material transport and handling – exact location tracking becomes a must. As discussed in part 1 of this blog there are various methods to achieve this, but the quasi industry standard is using RFID.

How does RFID work ?

Every carrier to be tracked needs to have some form of a RFID pill or RFID tag attached to it. This tag holds information about the tracked carrier, for example the carrier ID. In order to locate a carrier every place where a carrier can be placed needs to have an RFID Antenna which can detect and read the RFID tag information.

There is a fundamental important (and kind of hidden) meaning in this statement:

every place where a carrier can be placed needs to have a RFID Antenna

For true 100% location tracking no carrier is allowed to be placed somewhere without a RFID antenna. (classic examples for this could be shift leader tables, WIP overflow shelves, …)

When introducing RFID based carrier tracking a lot of existing FAB policies will need to change – but more on that later.

Here is a picture about the general infrastructure needed:

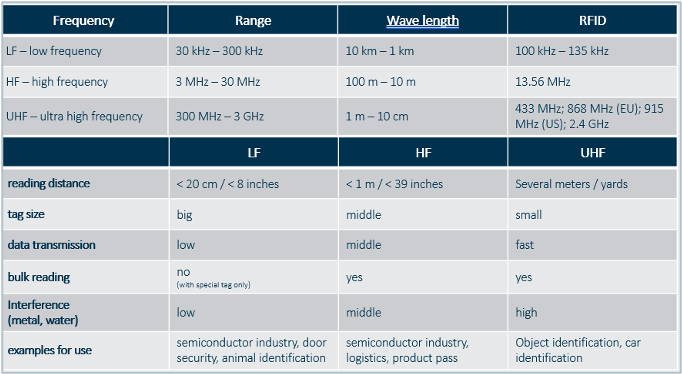

There are different frequencies for RFID system available on the market:

All of them have their individual strengths and weaknesses, but in the semiconductor industry the low frequency or LF is the quasi standard. Greater 95% of all FABs which use RFID based carrier location tracking use LF – biggest reasons for using LF are:

- very short reading distance (avoids cross reading of multiple RFID tags , for example in shelves or nearby load ports

- very narrow bandwidth ( helps in the general high radio frequency noise inside the FABs)

- plenty of different antennas available to accommodate antennas to be placed in difficult physical locations (like tight load ports)

Like already discussed in part 1 of this post there are many benefits of having good location tracking in place:

- no more time lost for searching carriers (lots)

- effective FAB scheduling is possible

- basic enabler for automatic material transport and handling

- basic enabler for automated process start on equipments

What makes RFID based material tracking the better choice over bar code scanning based solutions are things like

- highly reliable (not dependent on good lighting)

- many tool load ports come standard with RFID reading capabilities or can be easily upgraded

- no human interaction needed (hand scanning) – massive time savings possible

A few thoughts on how to approach an project to change a FAB to RFID

Introducing or changing carrier tracking methods are a complex task since a lot of existing policies might change. Change in itself always brings some risk with it and if it is involving possible productivity and/or wafer loss – sensitivity is extra high. Since every FAB has some form of carrier identification and location management in place (see part 1 of the post) the desire for change and improvement typically comes from cost pressure – either reduction in operator cost and/or growing plans to automate carrier transport, handling and decision making

A fundamental decision to be made at the very beginning of such a project is:

What is the end goal – in 5 or 10 years ?

What is the expected automation level of the FAB in 10 years from now ? Will the FAB always have operators or is the plan to have eventually 100% automation of “everything” ?

The statement:

every place, where a carrier can be placed needs to have a RFID Antenna

often raises fears on the overall cost of such a project.

But at a second look there is seldom a big bang event possible, where “overnight” everything has to be changed and in place. One big advantage of RFID based ID and location tracking is: It can be easily implemented in phases. In other words, there can be a long lasting hybrid approach used. Some areas start using RFID other keep doing what they do today. There might be even cases in older legacy FABs where not all locations and equipment load ports can be outfitted with the needed RFID hardware – but why not harvesting the benefits on 85% of all the others ?

The only true initial cost is that all to be tracked carriers need to have an RFID pill or tag attached to it.

What will it cost ?

Let’s assume the FAB has 6000 carriers (cassettes for example).

Depending on the RFID tag or RFID pill vendor, the cost should be around $10 or so. So we are talking $60,000 for the whole FAB.

In addition, there might be cost on how to attach the pill or tag to the carrier. This depends on what is already available at the existing carrier. In the best case there is zero additional cost (pill or tag holder already existing) or there will be very manageable additional cost to weld holders on the carrier.

The bigger cost driver is the actual roll out of the RFID antenna / reader / Ethernet connection boxes. The good thing is, it can be rolled out very step by step. For example: to start with RFID antennas for a certain tool group, just the RFID reader hardware needs to be procured and installed on these tools. This is anyway a recommended great 1st step to iron out any possible integration efforts with the local FABs MES system. Once this is working – maybe even including “load and forget” scenarios to automate process starts on the selected process equipment – further roll out can be planned better.

Using this approach the total project cost can be distributed over years if desired and the most beneficial tool sets (high operator effort for example) could go first …

Final Thoughts

For existing legacy FABs with aged process and metrology equipment one key aspect of such a project is to make sure that all desired equipment can be upgraded with reliably working RFID reading hardware.

I strongly recommend to partner with an RFID expert like (spoiler) FABMATICS (LINK) to test in your FAB at your specific equipment which antenna and reader combination works best for each tool type, shelf or buffer location- at the lowest possible cost – basically mounting RFID tags and antennas in various positions with actual carriers.

If you are early in your project and still free in decision making, here is my general recommendation:

- partner with an experienced RFID Semiconductor FAB retrofit company, not only for hardware and software, but also for the general concepts ( for example should you use re-writable tags or not as well as what capability you MES can provide)

- go with LF RFID solutions – if possible with pills

- plan for complete full automation in the future, to make sure your RFID infrastructure selection can support this longterm (number of different antenna types possibly needed) as well as AMHS and robotic systems which support RFID based ID tracking (way more reliable than bar code)

- plan to start with a pilot tool set

- run this pilot in production for some time and learn

- roll out tool group by tool group