When looking on the topic of improving Wafer FAB performance – the topic of lot and/or carrier tracking is often not in focus. For fully automated 300mm FABs this is really not an issue, because it is fully covered using RFID tags/pills on the FOUP and have any possible place where a FOUP can “sit” outfitted with RFID antennas. This ensures that at all times the exact location of a FOUP (and the associated lots) is known.

For legacy FABs running 200mm or 150mm the topic of carrier and lot location is far from being standardized and solved.

Why is it important ?

In Lehmans terms: if the location of a carrier (and the lot or lots) is not exactly known, it might create wait time and lost tool utilization since “someone” needs to “search” for it. These little search times can easily add up and become a problem. If a FAB wants to go from a more manual material transport and handling to a more automated solution the topic becomes very critical.

But even in manual FABs the real time knowledge of the current location of a carrier can have big impact.

A typical use case is to move from pure lot dispatching towards lot scheduling to improve the overall FAB cycle time and tool utilization. Without exact lot location a schedule is “worthless” since the schedule can not be executed. Because the lot is not available when needed. I have in person witnessed legacy factories which had scheduler deployed, but more than 10% of the WIP’s location was not known and therefore the schedule could not be executed. Typically the quality of the scheduler solution gets questioned , but the real problem is the unclear lot location data situation.

Let’s explore the situation – specifically for not fully automated factories

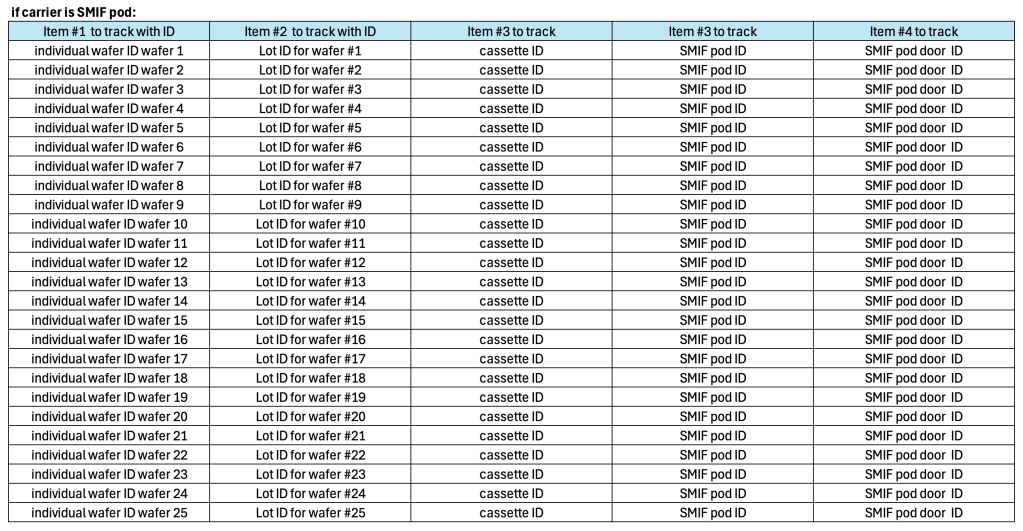

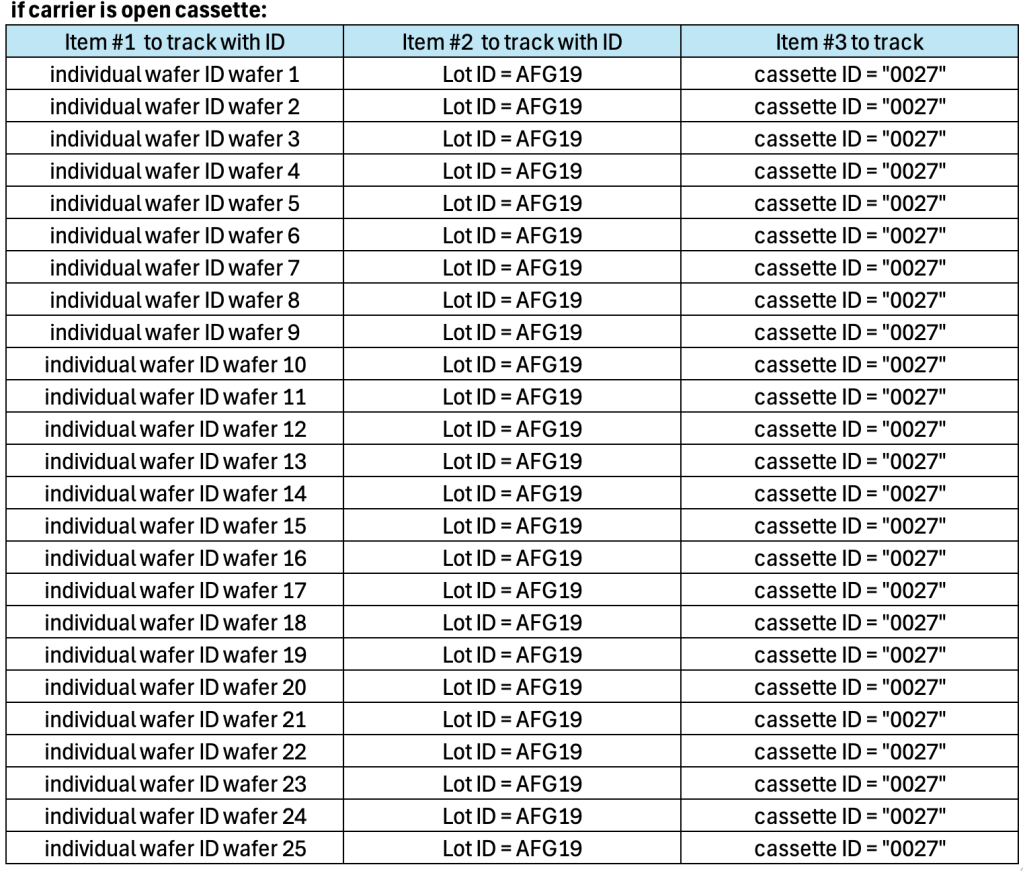

The first interesting thing to discuss is the lot and carrier identification itself. Depending on the used carrier in the FAB the complexity is different. The tables below show the theoretical depths of the problem:

For practical reasons not all of the items might be tracked in the real FAB application.

How are the individual parts ID’ed ?

There are different methods used for different parts.

Wafer identification

Individual wafers are typically tracked by using a physically laser scribed ID number directly on the wafer. This means the ID is fix for the lifetime of the wafer – it cannot really be deleted and given a new ID.

A lot ID is not a physical thing, which can be location tracked since a lot ID is a virtual entity residing in the MES. Multiple individual wafers (and their ID number in the MES) are logically grouped and called a “lot”. Common approach is that all wafers of one lot have the same target product and will be put in the same carrier. The mapping of wafer ID to lot ID traditionally happens at lot start in the FAB and will be stored and tracked in the MES.

Cassette identification

In the early days cassettes were ID’ed by putting labels with a form of code – typically bar code – on it. Additionally to the bar code there is often a human readable number on the label. To locate a cassette for example in a WIP rack, a human would scan with his/her eyes the rack until the cassette is found.

Example:

In the example above only 2 ID would be visible to humans or machines on the physical cassette: the cassette ID and if looked very close, the individual wafer IDs. The lot ID is usually not visible on the cassette, unless an additional lot ID label is recreated and attached to the cassette.

Therefore humans in the FAB often look for the visible carrier ID when searching for “a lot” but not really for the lot ID.

Using barcodes on the cassettes brought the advantage to use bar code scanners for data entry into the MES and therefore eliminating possible human errors while manually entering awkward lot and carrier ID into a computer terminal. Downside of the label with code method is that there are physical code scanner devices needed – many of them. In the real FAB 24/7 often these scanners create problems, especially if they are wireless and have rechargeable batteries. Network stability in fully packed legacy factories is often a challenge and battery life as well is “where is the scanner ?” create additional risk for lot processing delays.

A second – way more capable method of ID-ing cassettes – is the usage of RFID tags or pills. These pills can hold multiple sets of information and can easily be re-programmed with new content. The possibilities and advantages of RFID based carrier identification and location tracking will be topic of part 2 of this post.

Lot box identification

If a FAB uses cassettes in a box another element for tracking comes into play,. Should the box be tracked with an ID for the box itself on top of the cassette ID ? In my opinion the answer is yes. There are many advantages of doing so:

- boxes and cassettes might be restricted for usage only in certain zones (FEOL, BEOL, Copper , …)

- in a manual FAB, the box is what humans will see in most cases (since the cassette is inside)

- when cassettes are loaded onto an equipment load port the empty box needs to be stored “somewhere”. In many cases the same box should be used again once the cassette is done with processing

- there are steps in the process flow, when wafers need to be moved from the transport cassette into a special processing cassette – without ID it will be a risk to mix ups

- in case of equipment break down during process wafers from multiple lots, cassettes and boxes might need manual recovery – huge potential of mix ups, if proper IDs are missing

One typical question which needs to be answered when setting up cassette and box ID is: How is the relationship between the 2 defined.

For example:

At lot start a brand new cassette and brand new box will get for the 1st time an ID label, lets assume

Cassette ID = WC0028 and the Box ID = WB0028

Wafer ID will be assigned to a lot ID and after that the wafers get physically moved into the cassette and the cassette into the box. What will be the FAB policy regarding to the cassette to Box relation ?

Option 1: WC0028 always needs to be in WB0028

Option 2: there is no hard requirement for following Option 1 always, WC0028 can be for example transported in WB0017, as long as such a change is tracked within the MES

Both cases have their pros and cons, but in my experience option 2 is the most used one.

There are also cases where the box itself is transparent or has a transparent window and the cassette ID can be read by humans through the box. In these rare cases sometimes the box is not tracked with an own ID – with all the downsides of that.

SMIF Pod identification

SMIF pods introduce a 3rd part which could be tracked since the “lot box” now is a Pod which has 2 individual physical parts – the dome and the door. In general all statements from the section lot box identification can be made for SMIF Pod as well. The most interesting question for SMIF Pods is:

Is there value in tracking dome and door individually ? The answer depends a lot on 2 things:

1. Has the MES the capability to easily track additional objects ?

2. Does the process provide contamination risk, if the wrong door gets put on a dome ?

Now that the basic principles of the identification of carriers are discussed, let’s look into the location tracking aspect. In general location tracking for my purposes here mean:

“to know, where a specific carrier (carrier ID) is right now in the FAB”

There are 2 sub topics here: “Where” and “right now”

“Right now” is a simple correlation to date and time. If this data is available and stored in a computer system, then also the historical positions of a carrier can be looked up. The more interesting part is the “where”.

Although there are tracking systems available, which track “indoor GPS style” using X, Y and Z coordinates, it is more common to have defined places as the “location”, examples:

- Stocker 17 in bay 5

- incoming WIP ETCH bay rack 1

- load port 2 at equipment ID ETC003

- shift supervisor desk in main aisle

- on cart 3 of intra-bay transport system

- WIP rack 22, position 6

- push cart 4 (on the way to Litho area)

All these “locations” have some context related information and humans will remember, where WIP rack 22 is physically located. The interesting aspect here is, that humans are capable to use relatively “vague” locations like “it is in WIP rack 17” to hopefully quickly find the specific carrier – by browsing the carrier rows and look for the carrier ID.

How is the “carrier ID to location” relationship established and available for users (humans or machines) ?

There needs to be some form of track in / track out mechanism into a specific loaction.

for example:

- when a carrier is placed into a rack , the carrier ID as well as the rack id get bar code scanned

- when a carrier is placed on an equipment load port, the carrier ID and the load port ID get bar code scanned

- when a carrier is placed on a WIP Rack, the location is manually entered in a MES terminal

- or in its simplest form, without any tracking: “all incoming WIP to this bay gets placed in to the “incoming WIP rack”

The quality of the location data and its resolution can have a big impact:

” it is in rack 17″ might be good enough for a human, but if there are plans to automate material transport “it is in rack 17” will be a hard showstopper or at least very time consuming for a robot to scan all possible individual rack locations.

In general it can be said, the better the location data resolution is, the faster a carrier can be “found”.

In fully automated 300mm FABs any possible location a carrier can be in is individually specified and has an individual location ID. These are used by the MES and MCS system. For legacy factories with 150mmm oder 200mm wafers this location resolution is much more coarse.

I’m curious what nowadays the typical location data quality is. If you have knowledge about this topic in 150mm and 200mm FABs ( please no 300mm data ) please answer the poll below:

I will share the results in part 2 of this post.

Thank you for reading.